Eric Matwe’s MailleTec Industries Is The Premier Manufacturer Of Welded Metal Mesh

In this edition of Blue Buddha’s Meet the Artist series, we’re heading up to Canada to get to know Eric Matwe of Swift Current, Saskatchewan.

If you’re newer to the world of maille, you might not recognize Eric’s name, or even his online handle, lorenzo. But you probably know some of the weaves he’s created, and you’ve almost certainly seen at least one movie or TV show with his work. (The Hobbit or Game of Thrones fans, anyone?)

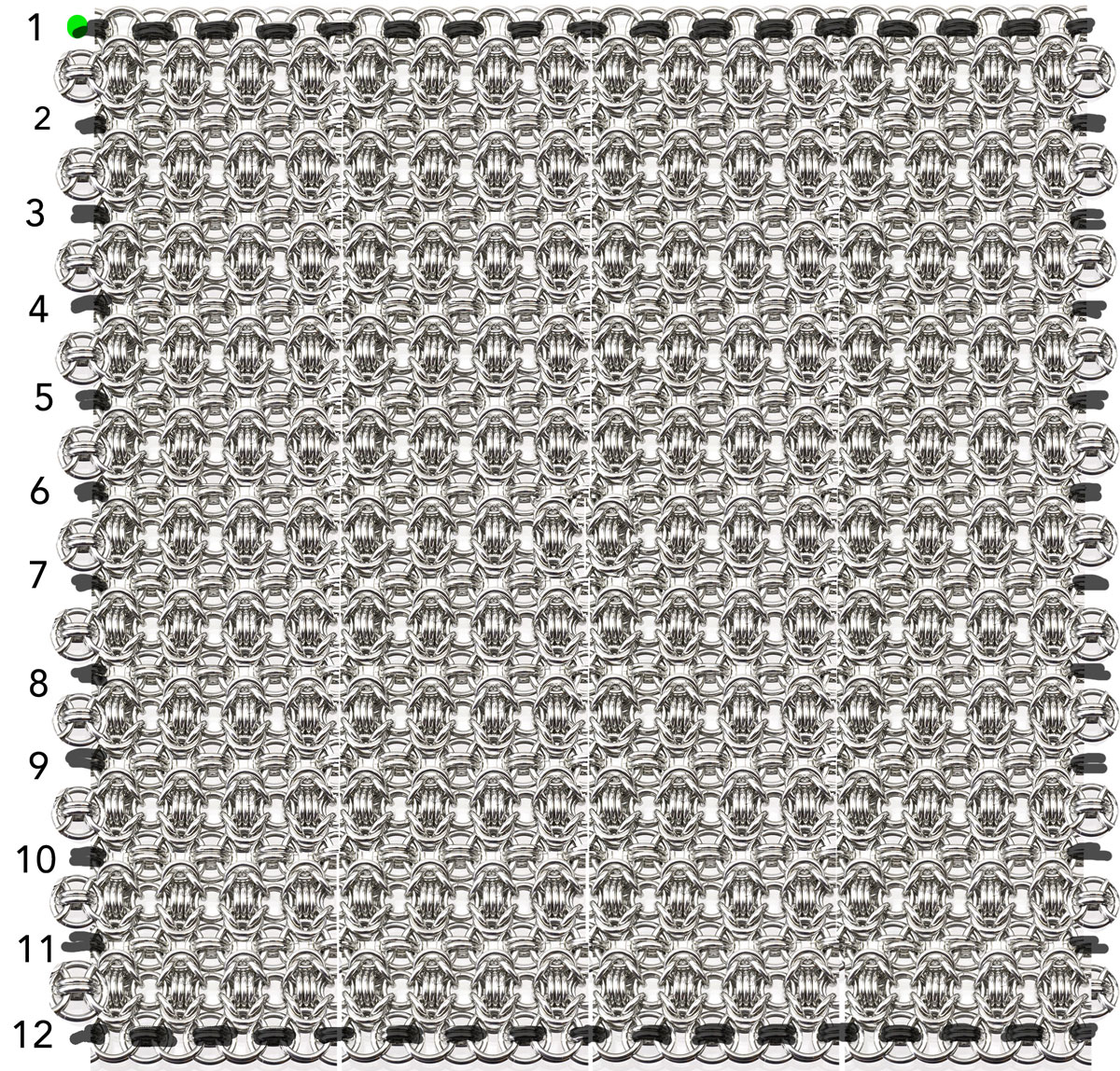

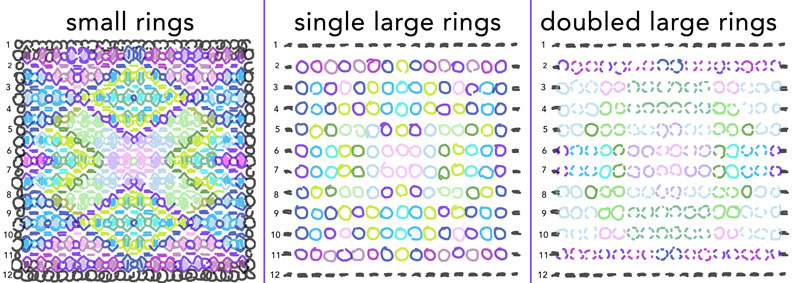

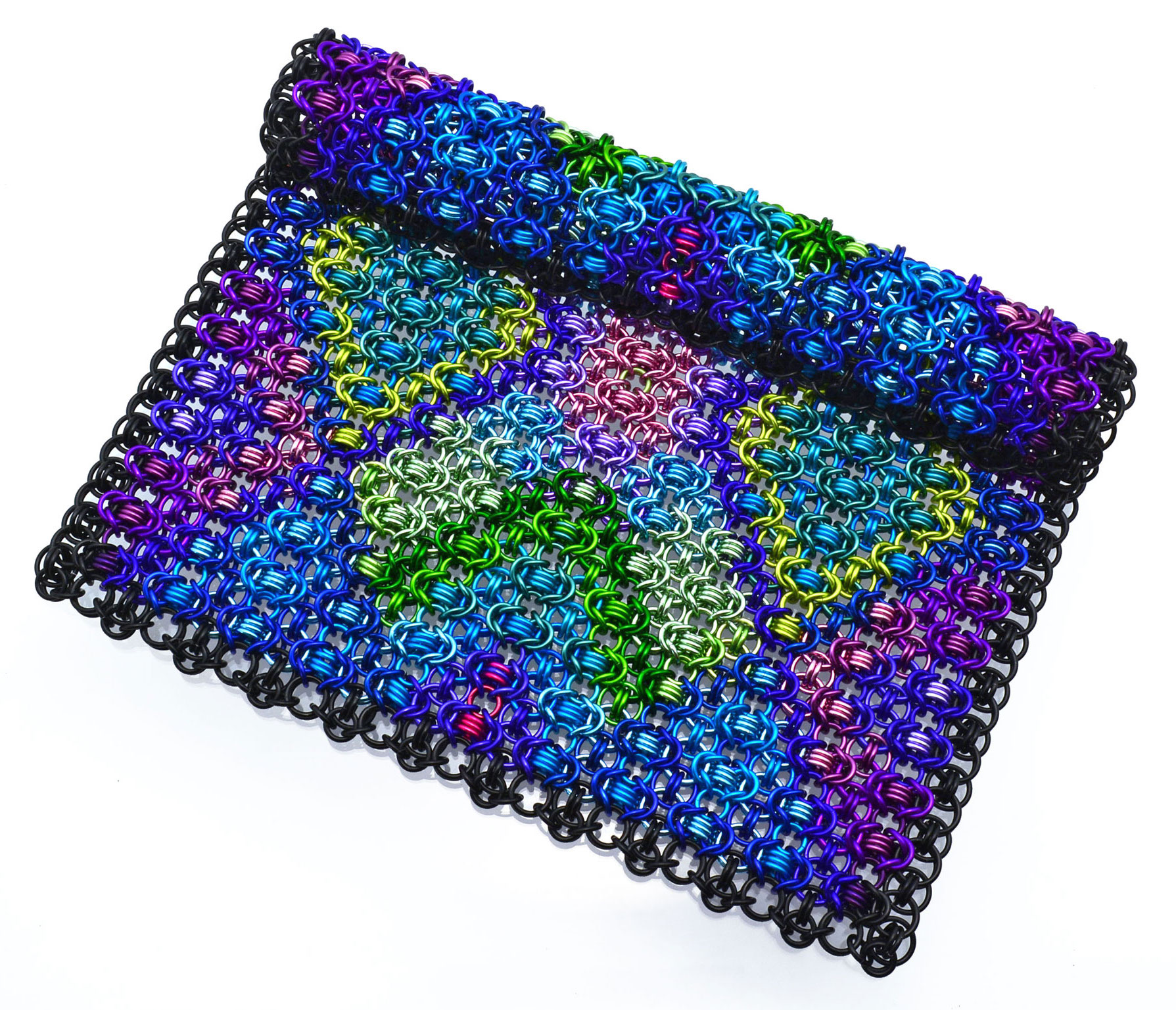

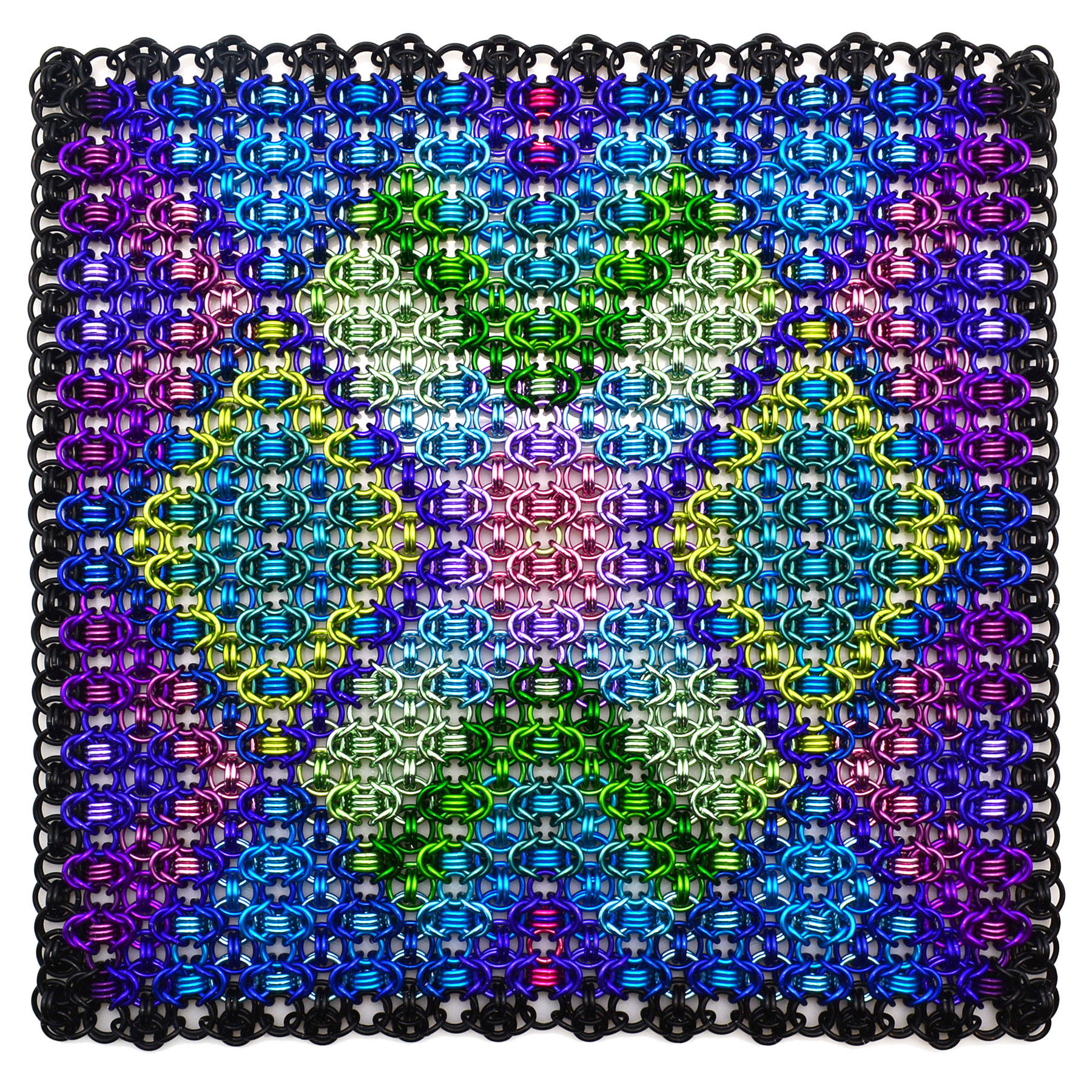

Eric’s company, MailleTec Industries, has been making welded maille for customers all over the world since 2010. Their maille is a flexible, beautiful and highly protective fabric and is used for industrial guarding, movie costumes, protective equipment, architectural installations, and more.

Let’s find out more about Eric and his company! (Be prepared to see some BIG sheets of mesh in this post!)

You’ve been doing this a long time. Exactly how and when did you get started with this craft?

I got started in the maille industry when I was 21, I had just dropped out of University and was trying to make enough money to pay for another semester towards a BFA. The best paying job I could find at the time was as a meat cutter at a meat packing plant in Moose Jaw, Saskatchewan.

The butchers gloves that were issued to employees there were in disrepair and it was common for us to end up with infected cuts from the knife tip going through a hole in the gloves. Well, I took my own glove home and fixed it up with some brazed stainless rings, a couple of the other guys at work noticed my glove was fixed and asked if I could do theirs too. After that word got around and pretty soon the company had me on contract fixing all the gloves in the plant.

The money was good enough that I decided not to bother going back to University, I bought a house in town and started working on some side projects with The Ring Lord in my spare time. I did that for the next 4 years until the plant finally shut down and we were all laid off. At that point the girl I was dating moved to Saskatoon to finish her university degree and TRL had been offering me a job for the last couple of years so I just sold my house and moved there to work at TRL.

I’ll always be proud of the things we accomplished at TRL. We worked very hard over the years to improve the quality and variety of products available to the community but in the end I just wasn’t a good fit there. I resigned from my position at TRL with no real clear plans. Over the next year we still collaborated on projects and I would come in and do contract work when they needed me.

At the end of that time they approached me with an offer to sell the machine made maille portion of the business. I had been the one who operated and repaired the machinery and they weren’t able to find anyone else who could do it. I accepted the offer but I knew I couldn’t manage it alone so I reached out to two other former TRL employees, I brought them and my wife on as partners and we incorporated as MailleTec Industries.

How has the industry as a whole changed since you started making maille??

Well, on the small business side it’s grown and diversified exponentially. When I started there was almost nothing; if I remember correctly, only Lord Randolph and Master Knuut were operating full time businesses. TRL didn’t exist yet, and options for rings and wire were limited and expensive. The craft industry that exists today is, I would say, largely built upon the work we did at TRL developing and improving products for all of you creative people to use in your work.

On the other hand, the large industrial concerns such as Whiting & Davis have declined. Corporate mergers and bankruptcies have resulted in almost all of those companies moving their remaining operations overseas. Of course there’s still a market for safety equipment but instead of a few dozen companies in that market there’s now two or three.

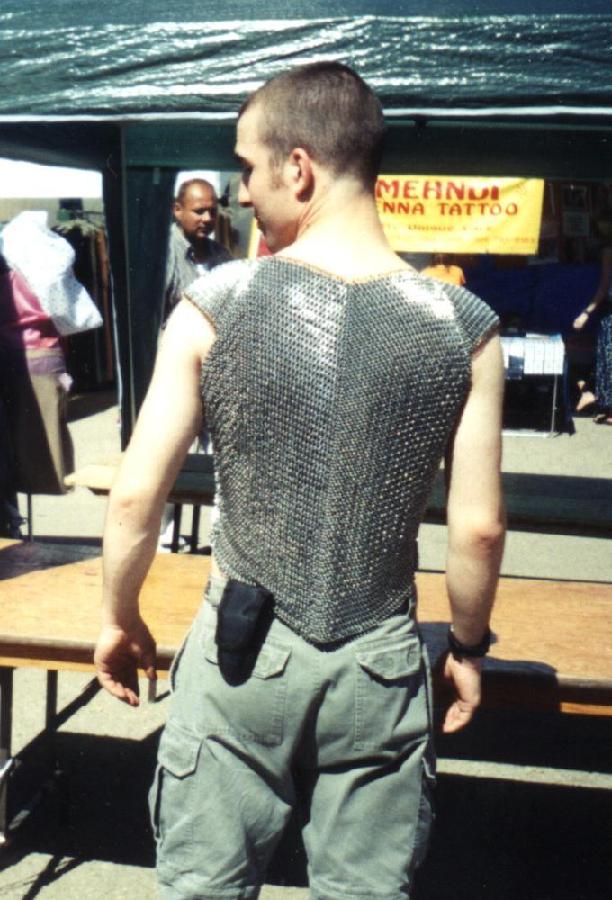

One of the first pieces of yours that I remember drooling over when I was starting my own maille journey in the early 2000s was your scalemaille vest. Can you talk a little bit about how that came together? I feel like you had to be one of the first persons (if not the first?) to make such a piece?

Sure. That scalemaille vest was the first of its kind. I designed the scales and the method of attaching them in 2001. I was inspired after hearing about the difficulties that Weta Workshop had in making scale armor for the LotR movies.

All of the options available at that time were bulky, inflexible, heavy, expensive and most of them were ugly to boot. My goal was to develop a system of scale armor that was simple, inexpensive, light, flexible and above all beautiful. I went through half a dozen linking systems before finally choosing the one we use now. It was the simplest and could be adapted to commercially available parts without too much expense. Aesthetically I chose the shape of the scales to mimic the look of a rattlesnake.

All of the options available at that time were bulky, inflexible, heavy, expensive and most of them were ugly to boot. My goal was to develop a system of scale armor that was simple, inexpensive, light, flexible and above all beautiful. I went through half a dozen linking systems before finally choosing the one we use now. It was the simplest and could be adapted to commercially available parts without too much expense. Aesthetically I chose the shape of the scales to mimic the look of a rattlesnake.

After that first prototype vest TRL assisted with funding that allowed us to order custom tooling and have the scales mass manufactured instead of punching them by hand. Eventually they took over manufacturing completely and have invested a lot financially into new scale product lines while I handled the bulk of the R&D for them.

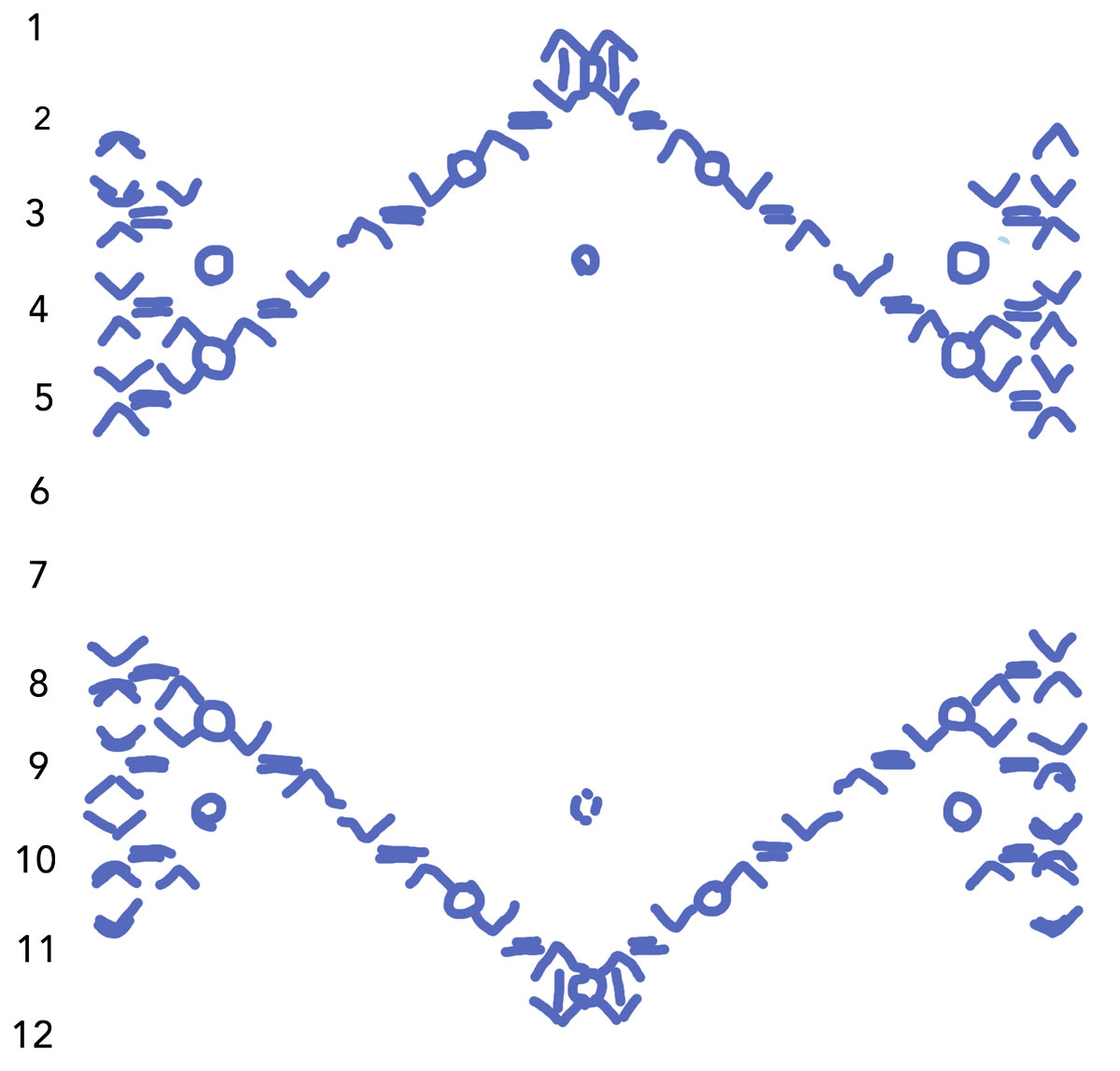

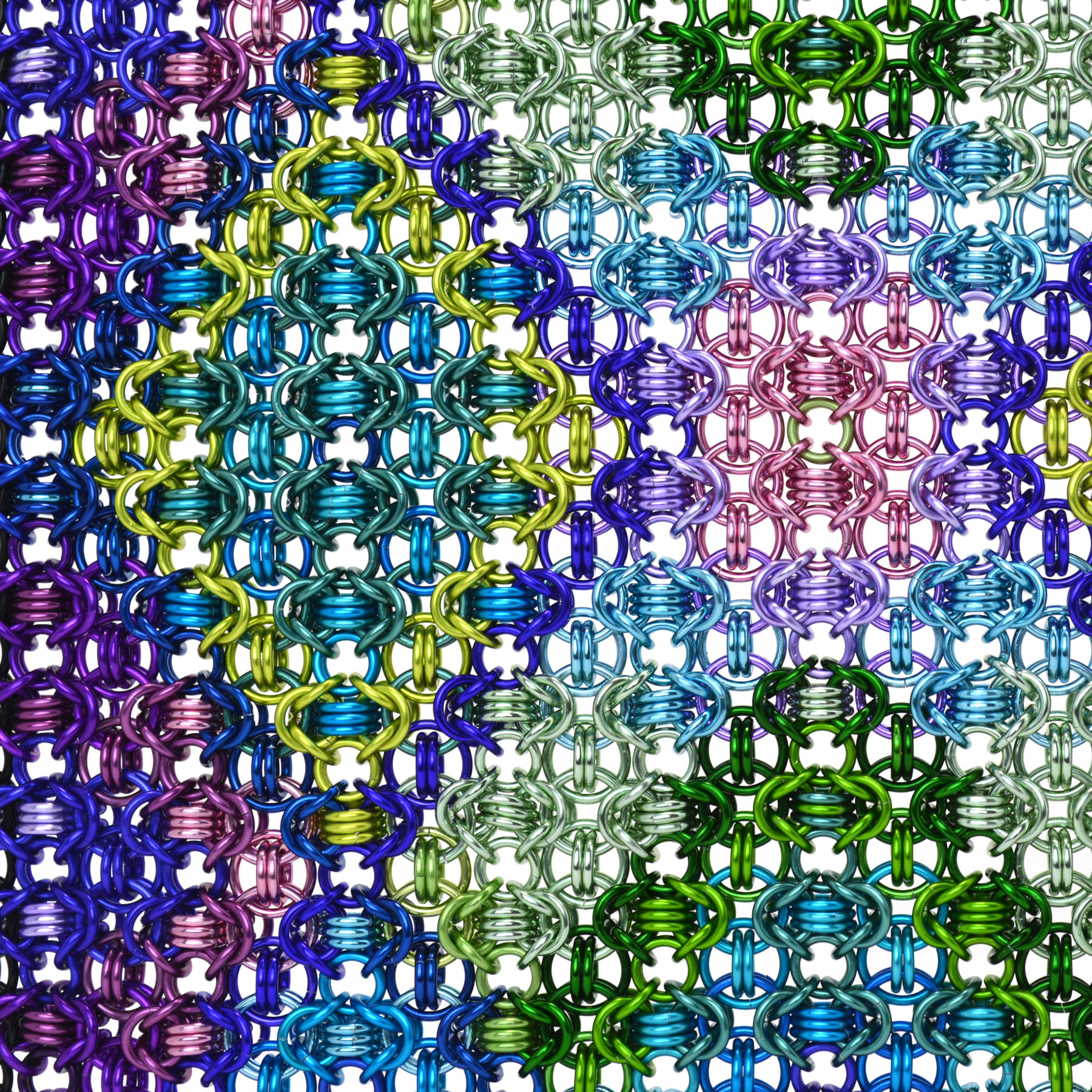

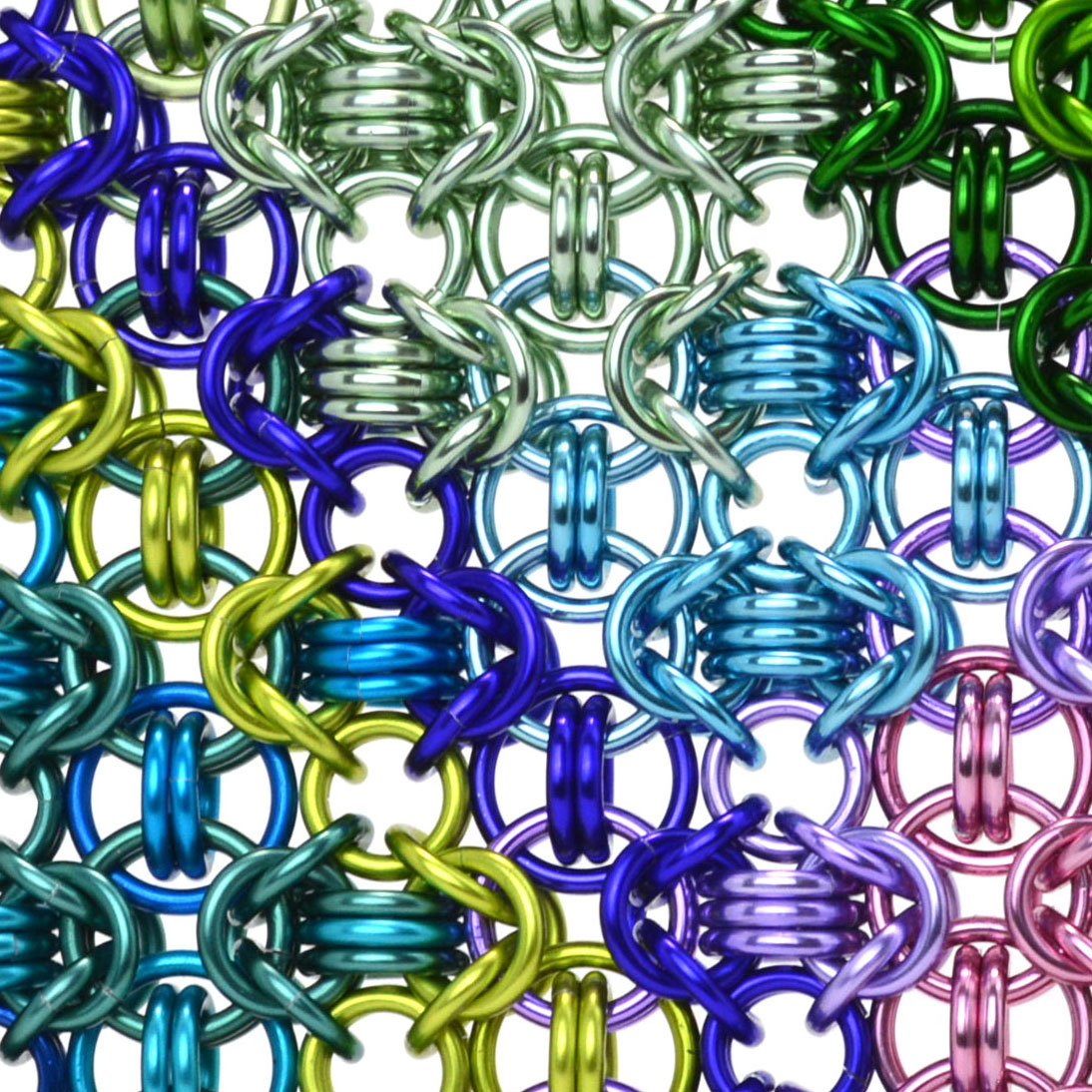

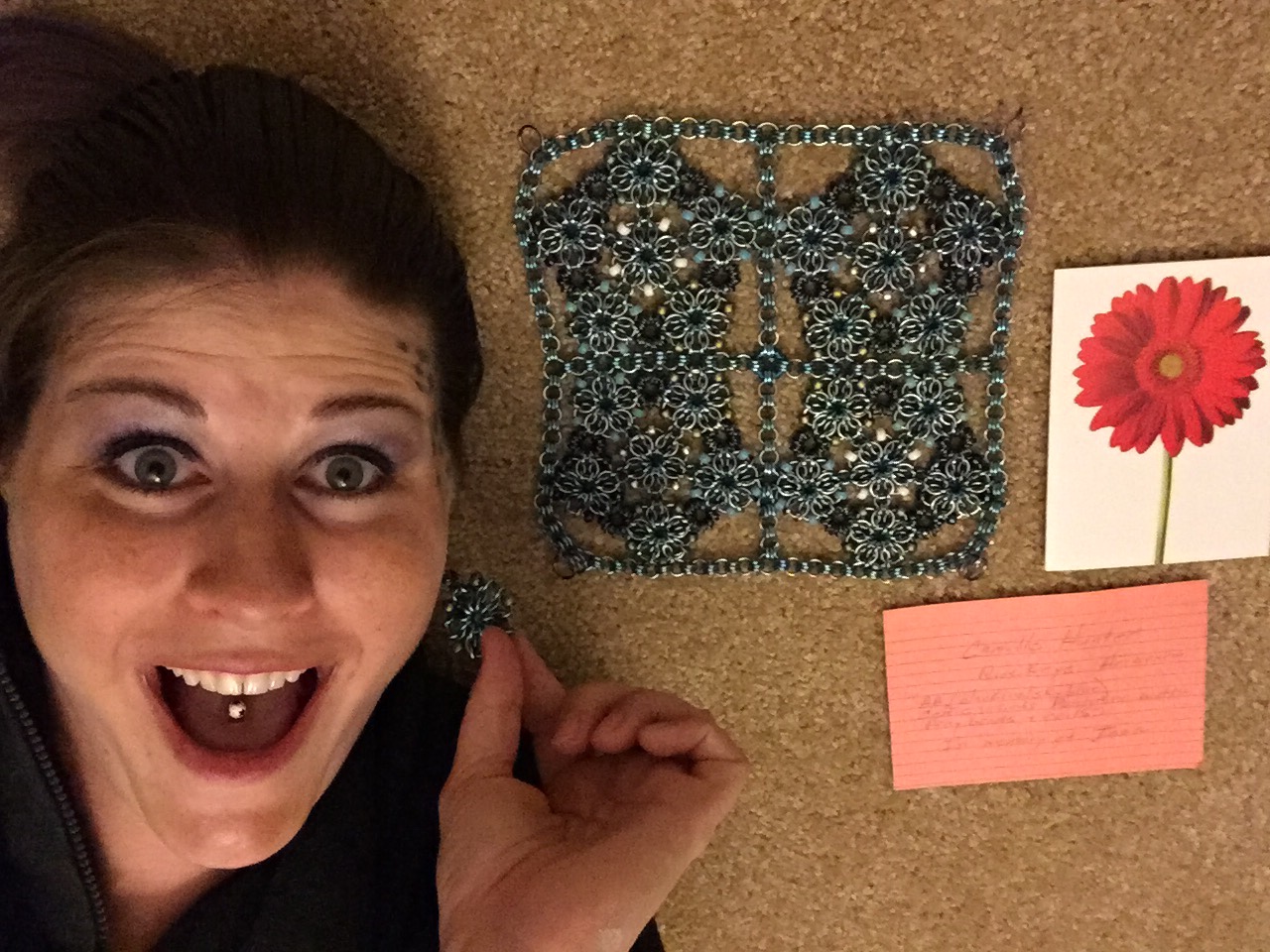

I thi nk two of the most significant weaves you introduced to the world are Captive Inverted Round and Trinity. Can we take a minute to talk about the Trinity shirt!?!? It’s amazing. What was the motivation to create such a masterpiece? Do you have the stats for it (# of rings, and/or anything else you’d like to share?)

nk two of the most significant weaves you introduced to the world are Captive Inverted Round and Trinity. Can we take a minute to talk about the Trinity shirt!?!? It’s amazing. What was the motivation to create such a masterpiece? Do you have the stats for it (# of rings, and/or anything else you’d like to share?)

Sure, so my motivation was to make the best shirt I possibly could at that time. I wanted something light, strong, flexible and pretty. I already had the rings woven into a E4-1 shirt, and it was strong but the weave was too tight, it was stiff, it was ugly and just didn’t fit right. The Trinity weave came to me in a fever dream one day and I just knew I had to convert it. The front, back and shoulders fell into place as if they were meant to be but the side panels took some work to get right. They’re J4-1 hung at a 45 degree angle for maximum stretch, which is how the shirt is so form fitting in a tight weave.

The rings are #10L mil. spec. lock washers and there are about 20,000 of them. The vest weighs just over 10 lbs. I wore it to a bar for Halloween ’97, if I remember correctly, and some guy straight up stabbed me in the back. So it probably saved my life, even though I’m reasonably sure he only stabbed me because I was wearing it.

What are some your favorite projects that you’ve worked on, and what were the challenges of each?

Well, besides what we’ve previously discussed, I really enjoyed making scale armor for The Hobbit movies. It was generally awesome to spend two weeks in New Zealand at Weta Workshop and meet some of the very talented people involved. More than that though it felt like coming full circle from my inspiration (LotR) to make better scale armor in the first place. There were a lot of challenges, design revisions mostly, and the pieces that made it into the final cut were nowhere near as epic as they were when we originally made them. They didn’t even get much screen time so it was a bit of a disappointment.

I’m very excited to have been a part of the NASA Mars Insight lander mission, I consider that to be probably the most significant project that I’ll ever work on. Having something that I invented and helped make with my own hands being flown to Mars is so surreal. It was an extremely demanding project, I had to modify our machinery to work with the Ti alloys. Getting the welds down to 0.01% errors with .5mm reactive metal wire was difficult to say the least. Besides that there was a lot of weaving to be done with the scale pieces and we were up against a tight deadline, everyone in the shop pitched in to get it done. I really hope that the experiment is successful and we will have helped advance human knowledge in some small way.

I also really value having worked for so many years with Neptunic, designing and manufacturing their sharksuits. I’ve spent months of my own time trying to work out better designs for the suits, getting feedback and slowly improving them. All things considered, that’s probably made it MailleTec’s least profitable product line but we’ll keep improving them as much and for as long as we can. It’s worth it to know that we’re helping to save lives, especially since most of those lives are working to protect the ocean ecosystems.

That’s really incredible! Anything else on the horizon that you’re excited to be working on?

Well, amazingly, the original patent for our maille making machinery was filed more than 100 years ago (!), in 1911 to be precise. The machines have been updated sort of piecemeal over the last century but have stayed more or less the same. I can’t get into too many details but we’ve been working on some new technologies to really bring maille back into its own in the 21st century.

Ooo, that *is* exciting! I had no idea the maille-making patent went back so far! I wish you much success and can’t wait to see what your company comes up with!

Ooo, that *is* exciting! I had no idea the maille-making patent went back so far! I wish you much success and can’t wait to see what your company comes up with!

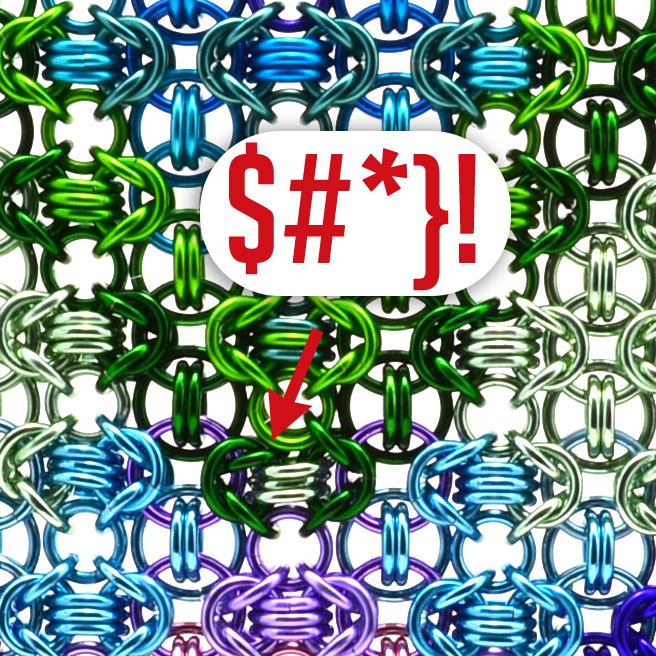

One of our blog readers would like to know: Have you ever hidden a secret message in any of your projects?

Yes.

Ha! That’s great. I’d ask what it was, but then I guess it wouldn’t be secret anymore. 😉

What is the best part of running your business? What was the most challenging part?

The best part is being able to work with my wife and my good friends as business partners. The most challenging part is the toll that working too hard has taken on my health.

Care to share a current goal?

I need to lose 40 lbs

What is one tool that you cannot live without?

Hmm… I make most of my tools, so I can usually just make more. I do have a ballpeen hammer that’s been passed down to me from my grandfather, I’d say that would be my most valued tool. It’s the only one I can’t replace anyways.

And now for the quick questions that I ask all participating artists:

Do you listen to music/podcasts/tv/etc while mailling? If so, what are your favorites?

Do you listen to music/podcasts/tv/etc while mailling? If so, what are your favorites?

Nope. Since I work with a lot of machinery I find that splitting my attention is counter-productive and sometimes dangerous.

What are your favorite artists (chainmaille or otherwise)?

As a Fine Arts dropout I have far too many favorites to list but Leonardo Da Vinci and M.C. Escher are likely at the top of that list.

What do you do when you’re not making chainmaille?

I make other things too, I dabble in a lot of crafts and I always have a couple of projects in process. I spend a lot of my time learning new things and I like to travel and spend time outdoors when I can. To relax I usually play video games with my friends and family.

What’s the best piece of advice you’ve ever been given?

Always keep an edge on your knife.

What would your superpower be and why?

Immortality, getting old really sucks and I hear dying isn’t great either.

What’s one thing Blue Buddha readers might be surprised to know about you?

I grew up in a house with no plumbing, heat or electricity.

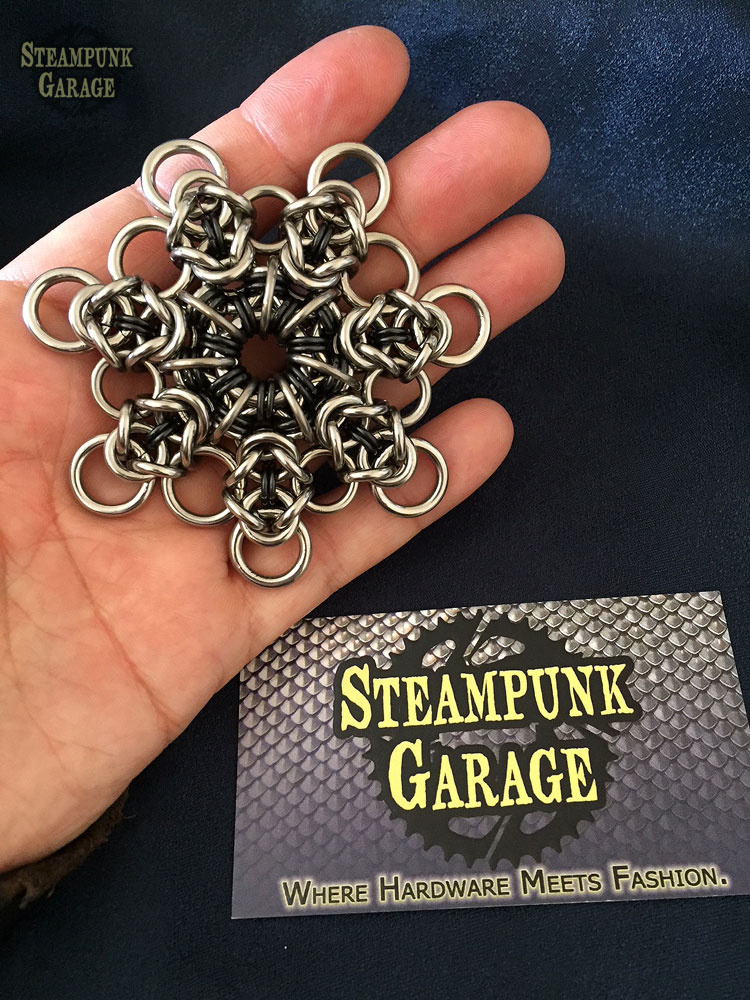

Before we let you go, please tell us where we can find your work!

MailleTec Industries, Inc.

Facebook: MailleTec Industries

M.A.I.L.: lorenzo

The Ring Lord Movie & Commercial Projects

Thanks so much for taking the time to chat with us, Eric!