We surveyed customers in July of this year to find out what website features they’d most like us to add. After adding a new feature that allows you to save multiple shopping carts and create chainmaille wishlists as well as a feature that allows you to shop from previous Blue Buddha orders, we decided to tackle the next most popular item from the list: back-in-stock notifications.

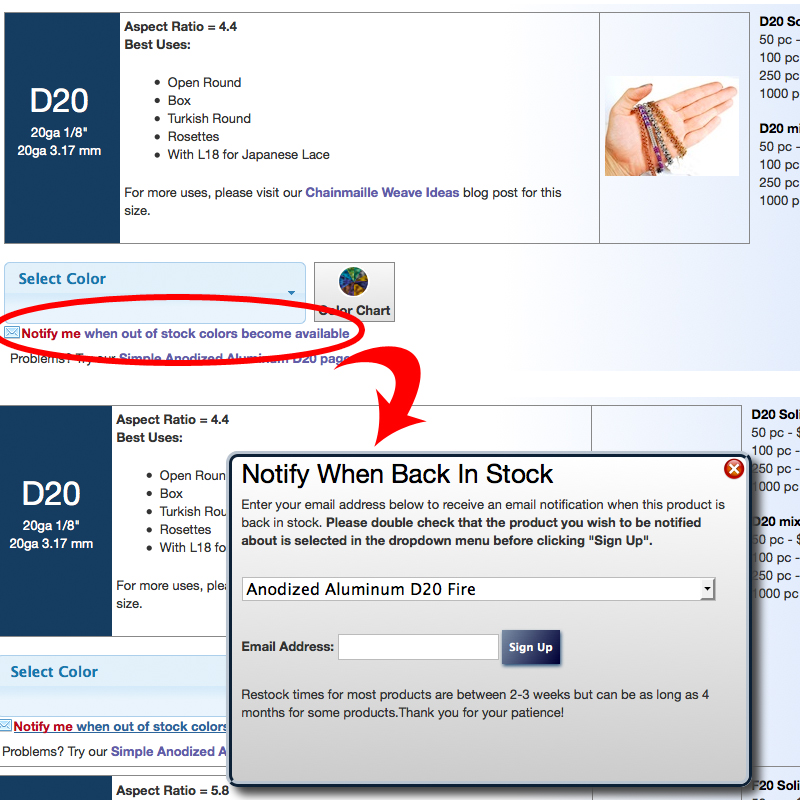

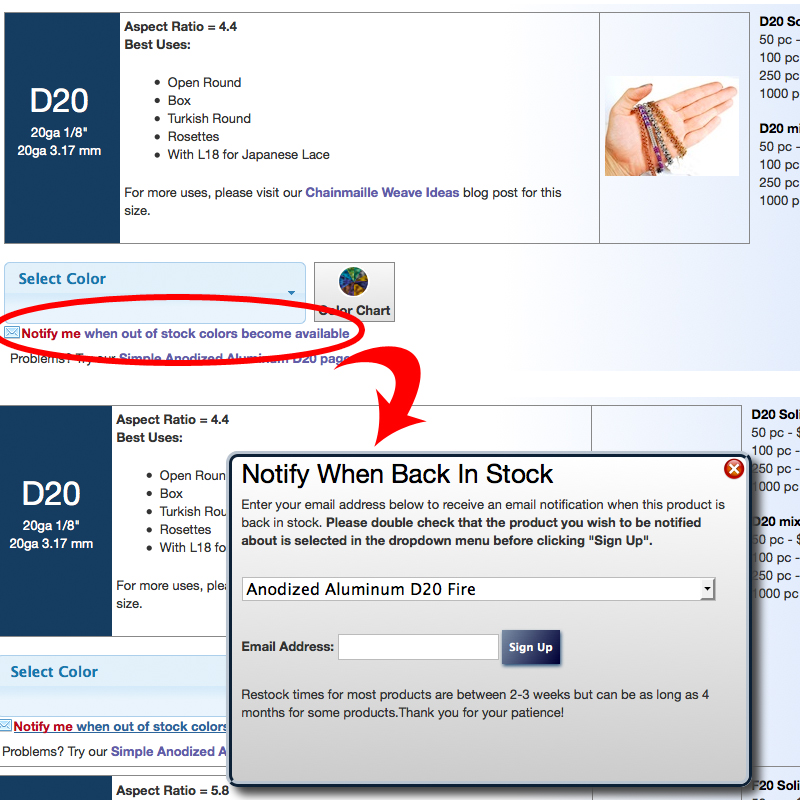

Now as you shop, you’ll notice little envelope icons that appear near “out of stock” items and colors. Clicking on that icon or the link next to is that starts with “Notify me…” will allow you to sign up to receive an email as soon as we mark the product as back in stock on the site. Pretty nifty right? Here’s a little tutorial on using this function:

1. Click the envelope icon to open the notifier window.

click for larger view

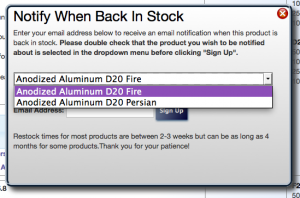

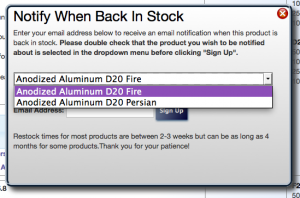

2. Use the dropdown menu to select the item you’d like to be notified about (don’t worry, you can go back and add other items from the list if you’d like to be notified about more than one.)

click for larger view

3. Enter your email address. Note: If you are logged in to our site, you email address should automatically appear in in this field.

click for larger view

4. Close the window or add more items from the dropdown.

Note: If you are not logged in to the site, you can only sign up to receive notifications for up to 6 items. We do this to help protect our site from spammers who like to use forms like this. If you are interested in signing up for notifications for more than 6 items, all you need to do is log in or create an account.

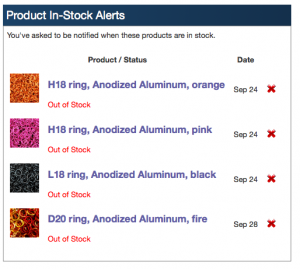

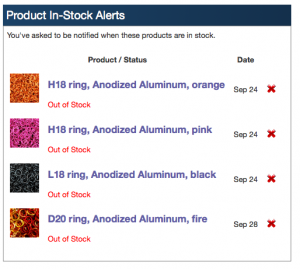

You’re done! You’re all signed up and will receive an email as soon as the item becomes available again. If at any time you’d like to see what items you are waiting on or delete anything from the list, you can log in and go to your “My Account” page. Down at the bottom of the page you will see all your back-in-stock notifications and can delete any that you like with a click of the red x.

click for larger view